Cast iron splicing plate

Name: Cast iron splicing plate

Proview: Docking platform

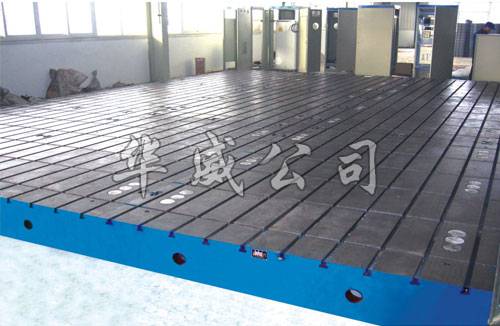

Next: Precision cast iron T-slot surface plate

Proview: Docking platform

Next: Precision cast iron T-slot surface plate

Specifications / Features

Cast iron plate splicing can also be called for large flat, (cast iron plate) can be used by a few pieces of flat stitching, through adjust the precision to be stable, commonly used in large venues construction, applicable to all kinds of inspection, measuring accuracy of datum plane for machine tool mechanical inspection measurement benchmark test, inspection of parts size precision or the behavior deviation and precision crossed, in the machinery manufacturing is an indispensable basic tool.Precision of cast iron splicing plate: according to the National Standard Metro logical Verification Regulation execution, respectively is 0,1,2,3, the precision plane five grades.

The iron splicing plate material and processing: materials for high strength cast iron ht200-300, working surface degree of hardness is hb170-240, after two manual processing (artificial annealing 600 degrees - 700 degrees and natural aging 2-3 years) enable the product accuracy and stability, good wear resistance.

Cast iron plate splicing specifications: 100*100 - 4000*8000 (special specification according to the drawings.)

Splicing plate flatness verification, and previous standards have not the same concept, use no longer blindly pursue splicing plate at the point of contact, the general use can focus on the flatness inspection, because now the work piece and the platform specification continues to increase, so on the measuring platform of the work piece requirements also change, the processing cost of the splicing plate at the point of contact and the number of test plate has a great relationship. Therefore, wise users no longer deliberately requirements splicing plate contact point.

Related product