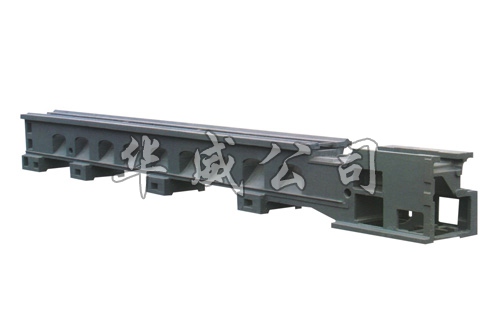

Machine tool bed

Specifications / Features

Characteristics of the machine: the lathe bed is machine based, machine bed to have sufficiently high static and dynamic stiffness accuracy retention, in under the premise of meeting the requirements of the overall design, it should be possible to do structural design reasonable, rib plate is arranged properly, but also to maintain the machine tool bed good cold and hot processing performance.(1) the machine tool wear resistance and anti shock performance. Because the graphite in cast iron is advantageous to the lubrication and the oil storage, therefore the wear-resisting property is good. Similarly, due to the presence of graphite, the shock resistance of the steel is better than that of the steel.

(2) the process of machine performance. Due to the high carbon content of the gray cast iron, close to the eutectic composition, so relatively low melting point, good fluidity, shrinkage of small, so it is suitable for casting of complex structure of lathe bed casting. In addition, because the graphite is easy to form a broken chip, the machinability of gray cast iron is better than that of steel.

Warwick company remind you: machine tool bed casting parts wall thickness should be as far as possible uniform, machine tool bed casting uneven thickness, easy to produce the shrinkage hole, shrinkage porosity, caused by casting machine bed deformation or produce a large internal stress, leading to the crack of the casting machine bed. Machine tool bed casting wall transferred or link parts easy to stress, shrinkage cavity and, should pay attention to prevent the machine tool bed casting wall thickness mutations and casting angle.

Therefore, in the machine tool bed casting wall of steering and wall joints shall be consider rounded structure to prevent the machine tool bed casting for metal accumulation and stress concentration resulting from the shrinkage hole, shrinkage porosity, cracks and other defects.

Related product